When a tiny component can force to do the dishes manually !

After a looooong period of procrastination, I finally decided to deal with my dishwasher. The soap dispenser wasn’t opening properly, cleaning results were getting worse, and my solution had slowly drifted toward either recycling dishes or running the machine in extreme 60 °C mode like a barbarian.

Before opening anything, I stumbled upon a video by Technology Connections explaining dishwasher cycles in absurdly great detail. Who would have guessed that the world of dishwashers could be that fascinating?

Highly recommended if you want to look at your kitchen appliances with new respect:

👉 https://www.youtube.com/watch?v=DAX2_mPr9W8

That video was the final push. Time to investigate.

———– LET’S OPEN THE VICTIM ——–

The soap dispenser was not closing anymore, it’s a very simple device: a small plastic enclosure, a spring-loaded trap, and a tiny actuator that releases the soap at a precise moment during the cycle. Simple, elegant, and usually very reliable.

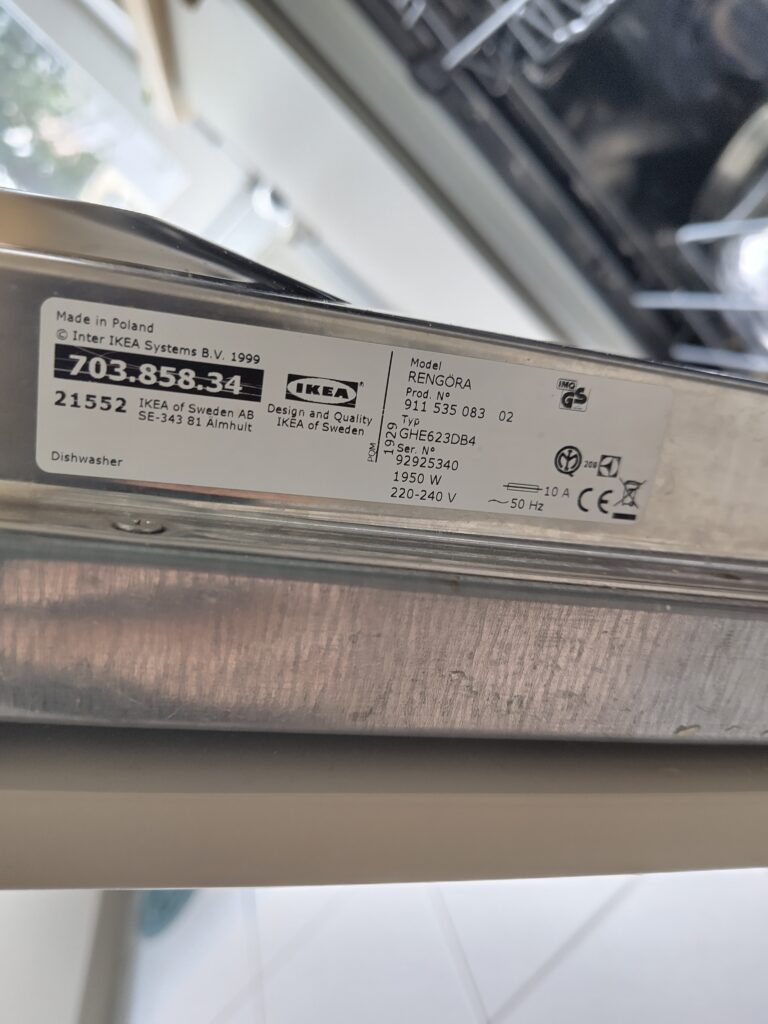

My dishwasher is an IKEA Rengöra (Prod. No. 911 535 083 02).

No big surprise here: most European kitchens are full of IKEA cabinets — and no big mystery either, IKEA doesn’t manufacture their own appliances.

In this case, the unit is an Electrolux OEM, clearly visible on the identification sticker.

———– Getting hands dirty ——–

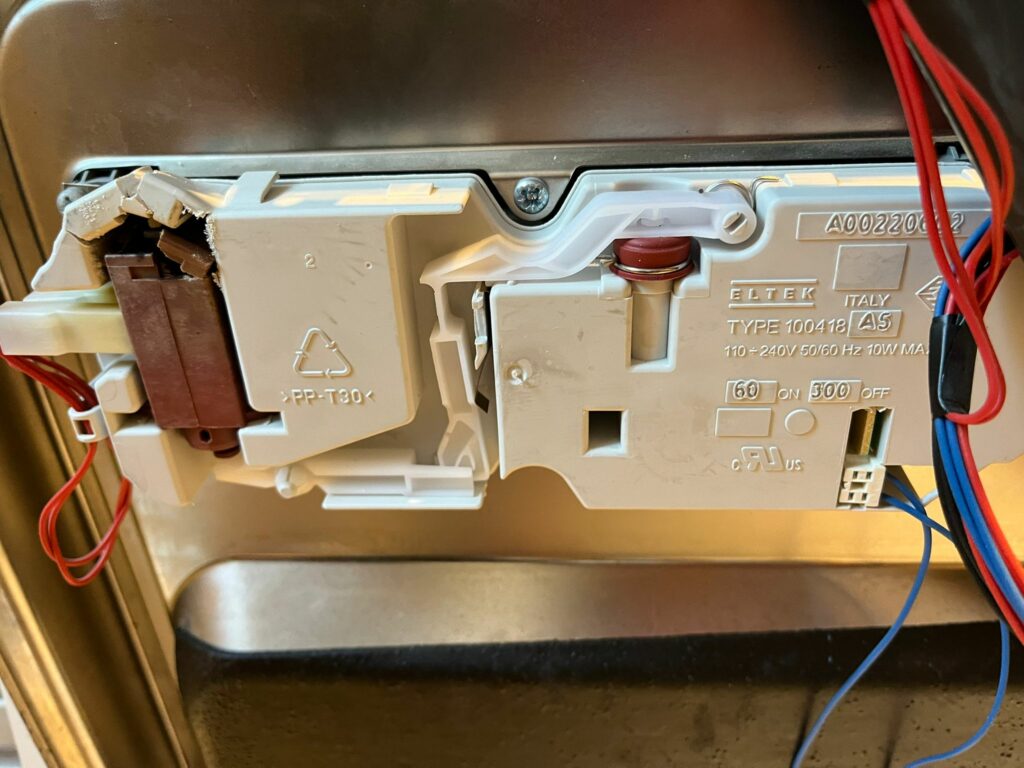

Opening the door panel was easy — just a few screws. As soon as it was open, the issue was obvious:

the mechanical actuator driving the soap dispenser was completely burned out.

I removed it, cleaned everything, and ordered a replacement using the remaining markings and a bit of Google Image magic. 20 € later, a new actuator arrived. Luckily, the surrounding plastic parts were enough and still usable.

Side note

This actuator is not a solenoid.

It’s a thermal actuator: a small heating element that slowly expands when powered, creating a linear motion that triggers the soap door. Slow, quiet, cheap, and perfect for this application.

— End of side note —

After installing the new actuator, I tested it — and immediately noticed something odd -> The actuator was constantly powered.

That’s not how it’s supposed to work.

It should only receive power at a specific point in the wash cycle. Constant voltage means it can’t reset properly… and it will eventually burn out again.

So the actuator wasn’t the root cause. Time to go deeper.

This meant pulling the dishwasher out of the cabinet (yes, hoses, water, fun stuff).

At the bottom, well hidden, sits the main control PCB, inside a white plastic enclosure.

⚠️ Important note:

I of course worked with the dishwasher completely disconnected from mains power.

This is not optional. This stuff can kill you.

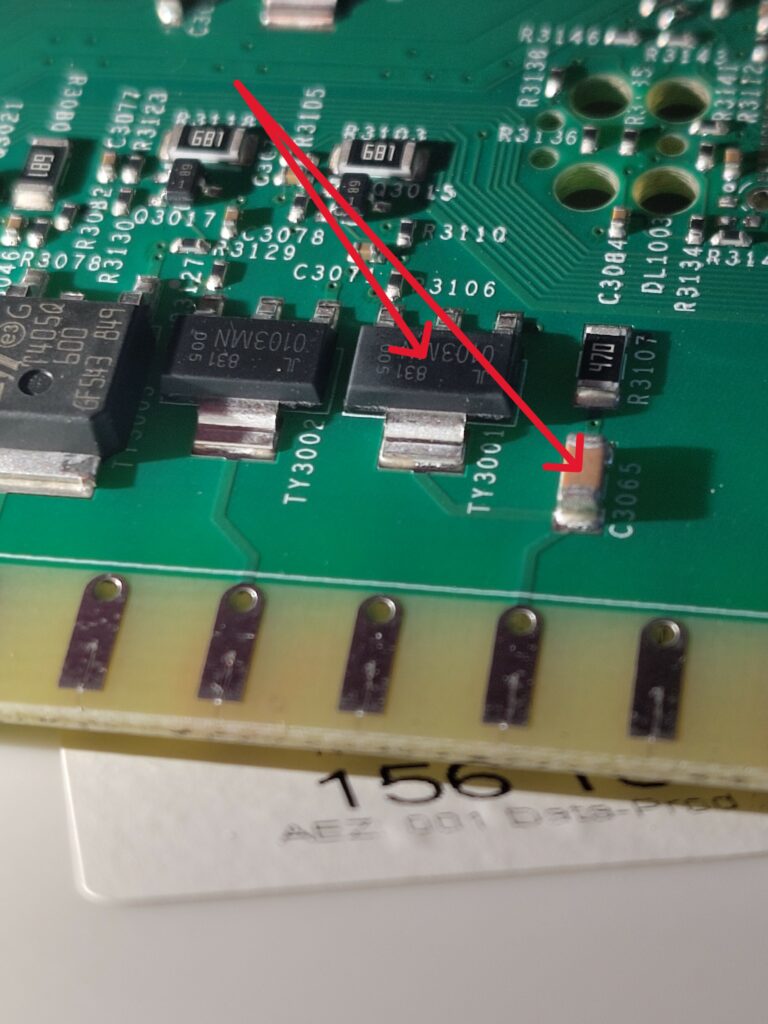

Tracing the wires from the soap dispenser led me to the PCB. There, I found a small triac controlling the actuator. 0103MN

https://www.alldatasheet.com/datasheet-pdf/view/293603/NXP/Z0103MN%2C135.html

Desoldered it. — Tested it. -> No issue. Triac was fine.

Testing a Triac with a multimeter is suprisingly easy : https://hubbellheaters.com/api/media/file/How_to_Test_a_Hubbell_Triac_Component.pdf

Then I noticed something else, Next to the triac was a tiny SMD capacitor, about the size of a grain of rice. After desoldering it, I noticed a microscopic hole in the casing — so small I only spotted it using my phone camera.

Measured it. -> Dead short.

Even more interesting: this capacitor didn’t look like a proper X2-rated capacitor, which is normally required for mains-related filtering. Suspicious design choice.

Luckily, the PCB had another identical circuit nearby, still intact. By measuring that one and checking the resistance of the thermal actuator’s heating element, I could estimate the correct value.

This circuit is a classic RC snubber network — used to:

- suppress voltage spikes

- reduce EMI

- protect the triac when switching inductive or thermal loads

It’s extremely common in appliance electronics.

I found a suitable replacement capacitor locally. Not SMD, not the same package — but electrically compatible. This was revival surgery, not aesthetic surgery.

Some creative lead extensions, a bit of glue, proper insulation, and the PCB was ready to go back.

——– DRUM ROLL ——-

Everything reassembled. Dishwasher back in place.

First test: voltage across the actuator terminals.

👉 0 V at idle — perfect.

Ran a full wash cycle.

Soap dispenser opened exactly when it should.

Success.